问题描述:

现况分析,Data Collection (4W2H Management):

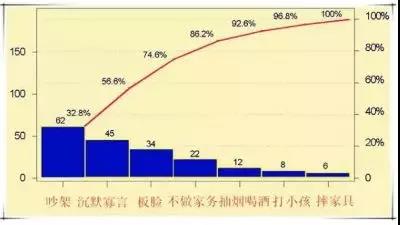

D4:Preliminary cause analysis and verification;Formulate and implement temporary countermeasures

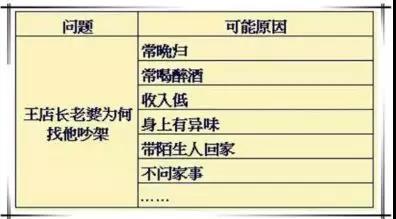

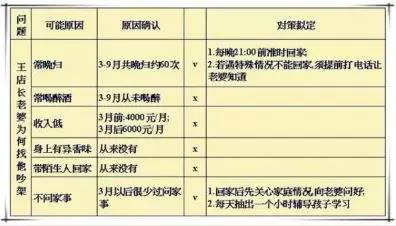

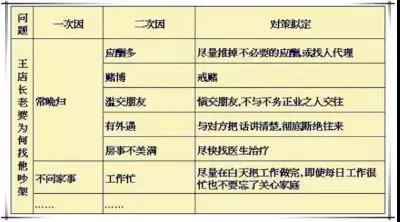

找出有可能原因:

系统图法:

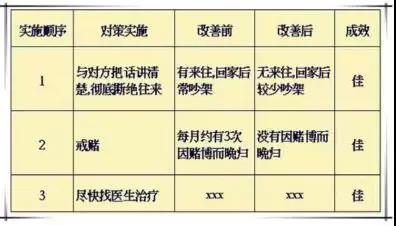

针对对策之效果确认:

D0:征兆紧急反应措施

D1:小组成立

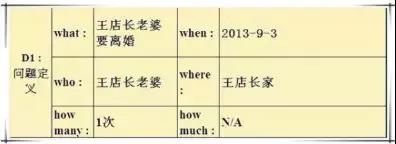

D2:问题说明

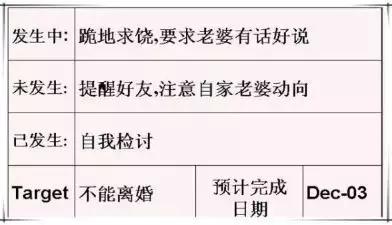

D3:Implement and validate interim measures

D4:确定并验证根本原因

D5:选择和验证永久纠正措施

D6:实施永久纠正措施

D7:预防再发生

D8:小组祝贺

D2-问题是什么?

D3~D6-问题如何解决?

D7-将来该问题如何预防

1.对零件的知识进行了充分的论证

2.完全确定了根本原因并聚焦于该原因

3.遗漏点已经被识别

4.确定与根本相匹配的纠正措施

5.纠正措施计划的验证已经被确定

6.包括了实施纠正措施的时间计划

7.有证据显示供方将把纠正措施纳入整个系统。

可靠性/设计验证DV/产品和过程确认/潜在失效模式及后果分析FMEA/控制计划CP/PPAP文件/SPC/DOE/QC7大工具

Key takeaways::Determine the type of problem、size、categories and so on。Unlike D3,D0 is the reaction to the occurrence of the problem,D3, on the other hand, is a temporary response to the problem with the product or service itself。

tool:Trend Chart/Permutation Chart/Paynter Chart/ERA(Emergency response measures)

Key takeaways::Membership,Craftsmanship、Knowledge of the product;target ;Division ;procedure ;Group building 。

tool:Action Plan、time management、Team Charter、Gantt Chart(Pilot)

"Something went wrong"

Key takeaways::Collect and organize all relevant data to illustrate the problem;A problem description is a summary of particularly useful data for the problem described;Review existing data,Identify the problem、Determine the scope;Segment the problem,Break down complex problems into individual issues;Problem definition,Find a description that matches the customer's identified issue,"Something went wrong",The reason for this is unknown risk level。

tool:Quality risk assessment,FMEA analysis,5W2H(What/Why/When/Where/Who/How/Howmany)、Line chart、histogram、排列图

Key takeaways::评价紧急响应措施;找出和选择最佳“临时抑制措施”;决策;实施,并作好记录;验证(DOE、PPM分析、控制图等)

tool:method:FMEA、DOE、PPM、SPC、检查表、记录表PDCA

Key takeaways::评估可能原因列表中的每一个原因;原因可否使问题排除;验证;控制计划

tool:FMEA、PPM、DOE、鱼骨图、头脑风暴&关联图、5why法、稳健设计

Key takeaways::重新审视小组成员资格;决策,选择最佳措施;重新评估临时措施,如必要重新选择;验证;管理层承诺执行永久纠正措施;控制计划 。

tool:FMEA、设计验证和报告(DVP&R)、因果图、稳健设计、检查表、记录表

Key takeaways::重新审视小组成员;执行永久纠正措施,废除临时措施;利用故障的可测量性确认故障已经排除;控制计划、工艺文件修改 。

tool::FMEA、防错、SPC、PPAP

Key takeaways::选择预防措施;验证有效性;决策;组织、personnel、equipment、environment、material、文件重新确定。

tool:FMEA、控制计划CP、过程流程图Flow-chart

Key takeaways::有选择的保留重要文档;流览小组工作,将心得形成文件;了解小组对解决问题的集体力量,及对解决问题作出的贡献;必要的物质、精神奖励。

source:Internet