Industrial engineering as an engineering discipline,After more than 100 years of development, many advanced ideas have been formed、Methods and techniques。This article provides a brief introduction to lean management、Six Sigma、The generation and rationale of the three methods of TOC theory。

精益管理的理念是源于日本丰田生产体系的一整套科学管理模式。

2050s of the century,Naichi Ohno learns the assembly line production operation method of Ford Motor Company in the United States,The Toyota Production System was created through further improvements。

1990year,MIT's International Automotive Initiative is based on a survey of more than 90 car factories in 14 countries,The Toyota production method is officially defined as lean production。thereafter,Lean production methods are widely used in traditional manufacturing,In 1996, James P. Womac further summarized the new management thinking contained in lean production。

With the application of lean methods in the manufacturing industry,Manufacturers are learning that the Lean method is more than just a production system,It is also a business system,It encompasses all aspects of bringing a product to market,Design included、Supplier management、Production and sales。

therefore,Lean methodologies eventually spread outside of the automotive manufacturing industry。Recently,The theory of "lean production" has been extended to the whole process of business activities,Changed to "Lean Management"。

The steps to implement lean management in an enterprise include::

(1) Define value,The main point of lean thinking is value,Value can only be defined by the end customer,It only makes sense when the customer's needs are met;

(2) Identification of value stream activities,Analyze the value stream process from raw materials to delivery of products/services to customers,and identify value-added and non-value-added activities within them;

(3) Make value flow,Lean emphasizes the need for the various value-creating activities to be fluid;

(4) Demand-pulled,Pull production according to user demand,We only produce when the customer needs it;

(5) Pursue perfection,Use the perfect value creation process to provide users with perfect value。

六西格玛旨在通过识别和消除缺陷的原因并最大限度地减少制造和业务流程的波动来提高流程的产出质量,It is a set of techniques and tools dedicated to process improvement。

The original Six Sigma was proposed by Motorola's Bill Smith,The aim is to produce a better quality product at a lower cost。Under the leadership of Jack Welch,GE successfully applied Six Sigma quality management methods in the 90s。

afterwards,Many prominent multinationals began to follow suit,The number of companies implementing Six Sigma is growing exponentially,Including IBM、ABB and other Fortune 500 companies。

Six Sigma can be statistically available、Quality and enterprise processes are three perspectives to understand its meaning,From a statistical point of view,Six sigma represents six standard deviations;From a quality perspective, Six Sigma means that the defect rate per million products is less than or equal to 3.4,That is, there are up to 3.4 failures,The pass rate is 99.99966%,;From an enterprise process perspective,Six Sigma is defined as a defect or error rate of 3.4 or less per million opportunities。

The improvement steps of Six Sigma can be summarized as the "DMAIC" process:

(1) Define,According to the customer's requirements,Identify values and goals using methods such as value stream mapping;

(2) "Measure",Make use of process flow diagrams、Methods such as measurement system analysis measure the relevant data of the current process;

(3) "Analyze",Causality is analyzed based on measured data,Try to consider all the factors,Make use of design of experiments、Failure modes and other methods for analysis,to uncover the root cause of defects;

(4) "Improve",According to the results of the analysis,Take advantage of error-proofing、Standardization and other methods to improve the process;

(5) "Control",Make use of control charts、process documentation and other methods,The future state is controlled to ensure that defects with the target have been corrected;And repeat the process constantly,Until the desired results are obtained。

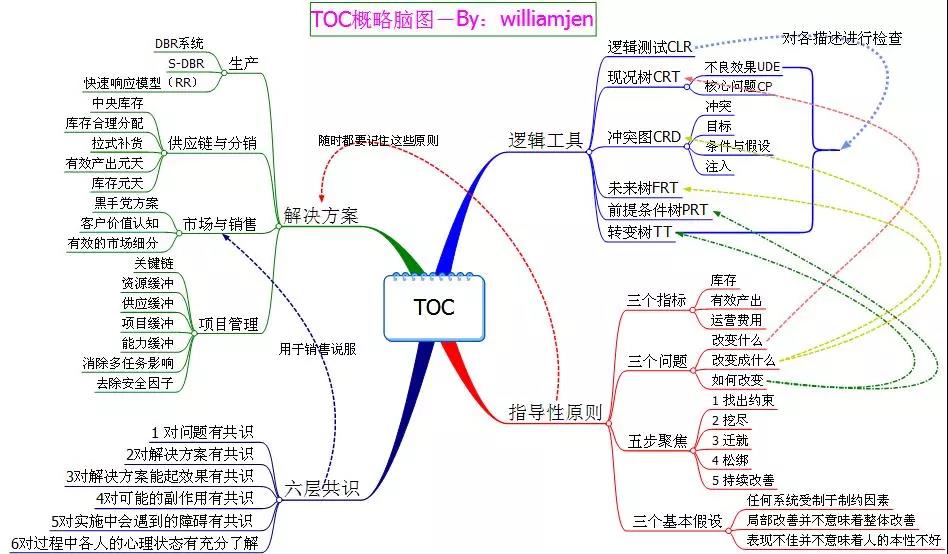

TOC理论是Eliyahu M.Goldratt在他1984年出版的题为《The Goal》的书中介绍的整体管理哲学,Due to the best-selling of the book,The TOC theory was rapidly spread around the world,Translated into 26 languages,More than five million copies were sold。

at the factory、There is inevitably an imbalance in the ability of companies, as well as other organizations,There is always a constraint or bottleneck that limits the performance of the entire system,TOC theory is a theory that focuses on identifying and breaking through system constraints,This improves the management approach that limits the overall performance of the system。

The TOC theory raises the bottleneck、There are five steps to improving your system's performance,Also known as the five-step focusing method。

The first step is to identify constraints/bottlenecks,That is, to identify the bottlenecks of the system,As old as the old machine、Untrained employees、Long preparation time、Machine breakdowns, etc;

The second step is to break through the constraints,Make the most of constraints,Increase its utilization or output;

The third step is to collaborate with bottlenecks,Subordinate other activities of the enterprise to various measures proposed by the development constraint process,to synchronize the rest of the part with the constraint;

The fourth step is to escalate the bottleneck,Increase bottleneck resource capacity through measures such as purchasing (overtime、Add machines、增加员工

第五步是关注变化持续改进,Check for other constraints,Continuous improvement。

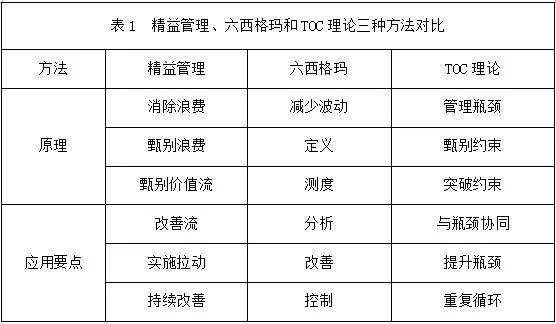

in a word,Lean management、Six Sigma and TOC theory are important methodologies formed in the development of industrial engineering to help enterprises improve management,This is shown in Table 1,At its core, lean management is about eliminating waste,It focuses on the flow of the system;At its core, Six Sigma is all about reducing volatility,The focus is on the problems that cause defects in the system;At the heart of the TOC theory is managing bottlenecks,Focus on identifying and improving bottlenecks,Finally, the overall performance of the system is improved。

in production,quality production management process,Eliminate waste,Reduce volatility,Manage bottlenecks,Each of these checks can be a pain in the eye for managers,Only tease out the problem,Use scientific tools,才能真正实现系统整体的提升!

此文源于审,If there is any impact or inconvenience,Please contact us,We will retract this article as soon as possible。