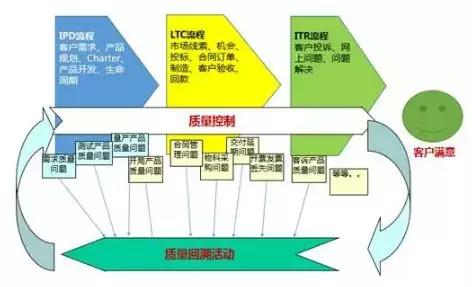

Quality backtracking is applied to the improvement of various issues in the company's three major business streams,It forms a closed-loop management with quality control,Guarantee continuous improvement,Improve the company's quality management level。

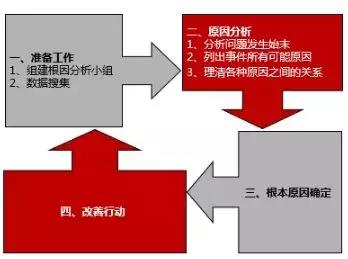

The following is the quality retrospective application model:Quality control and quality backtracking form a cycle,Ensure that problems in the operation of the organization are continuously improved,The result is increased customer satisfaction。

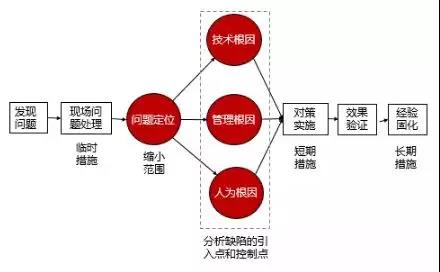

The mechanism of defect problems:

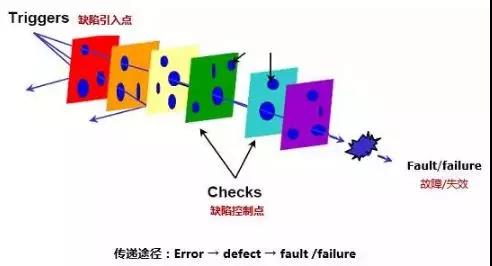

Defect:Errors are hidden in the product、in business,Defects are formed;

Fault/Failure:The final product delivered、Business Results,The desired effect was not achieved,Such as product failure、Business failure;

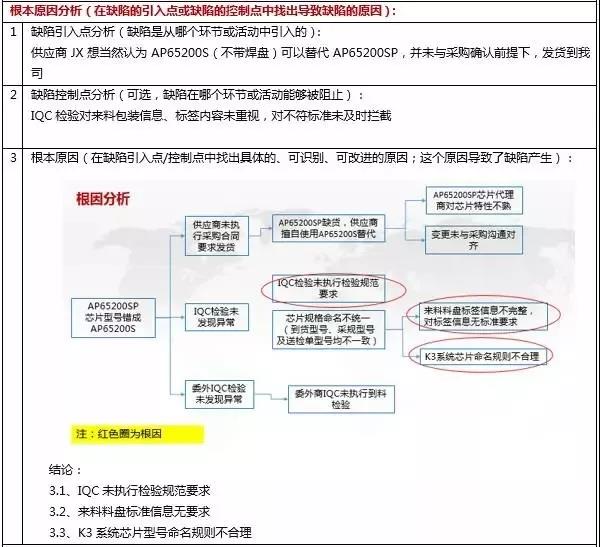

- 缺陷引入点:The root cause of the problem is usually at the "defect introduction point",For example,We organize a quality retrospective of customer complaints caused by a product failure,The software supervisor locates the root cause of a code writing error,Pointing out that it is the responsibility of an employee,The actual investigation shows that there are no writing standards and requirements for this kind of code,Each employee does it according to their own understanding,The code outputs are all different,The employee happens to be a newly hired software engineer,So the problem is flawed at the point of introduction:There are no writing standards and requirements for this type of code,Improvements revolve around establishing standards and specifications for writing code,Carry out standard popularization training。

- Defect control points:The root cause of the problem is usually not at the "defect control point",Control points are not the source of the problem。For example,The above product failure is a code writing error,In the course of internal projects,Control points have code reviews、Software UT、 SDV、SIT and other test control points,When organizing backtracking,We do use cases and perform analysis from each control point,If the fault is found at the time of the control point "Software UT".,Conduct a trace,It was found that there was a lack of logical use cases for the software UT control point。

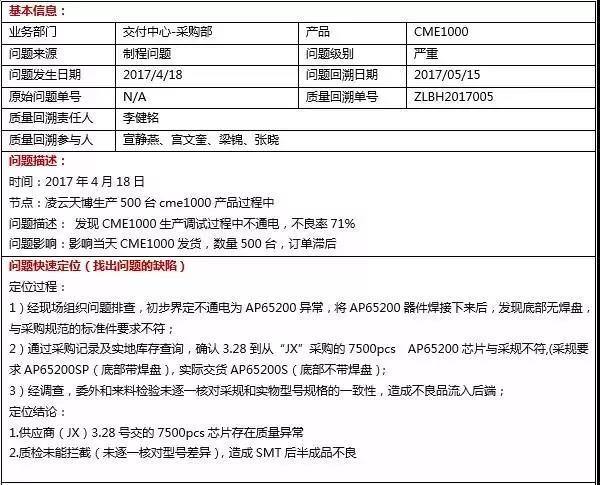

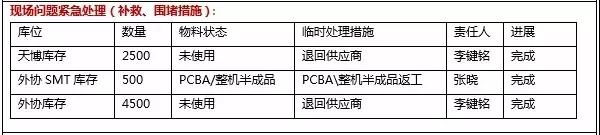

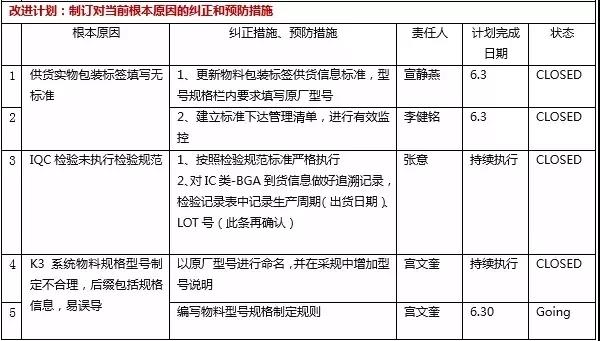

- This quality backtracking activity solves the problem of "wrong model of chip device procurement."、mixed" and other series of problems,Organize the formation of material packaging label model standards,Optimization of incoming inspection standards (increased part number extension inspection items),Traceability management of IC incoming inspection records,Material procurement, device model concretization, etc;

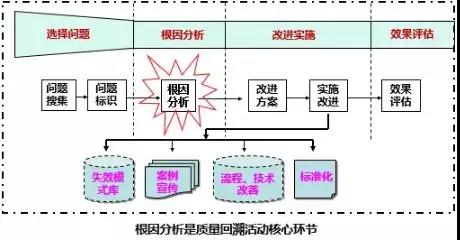

- The backtracking process is simple and clear,Directive,The group applied brainstorming in the process of cause analysis、system diagrams and other quality tools。